Swerock AB, Skara, Sweden

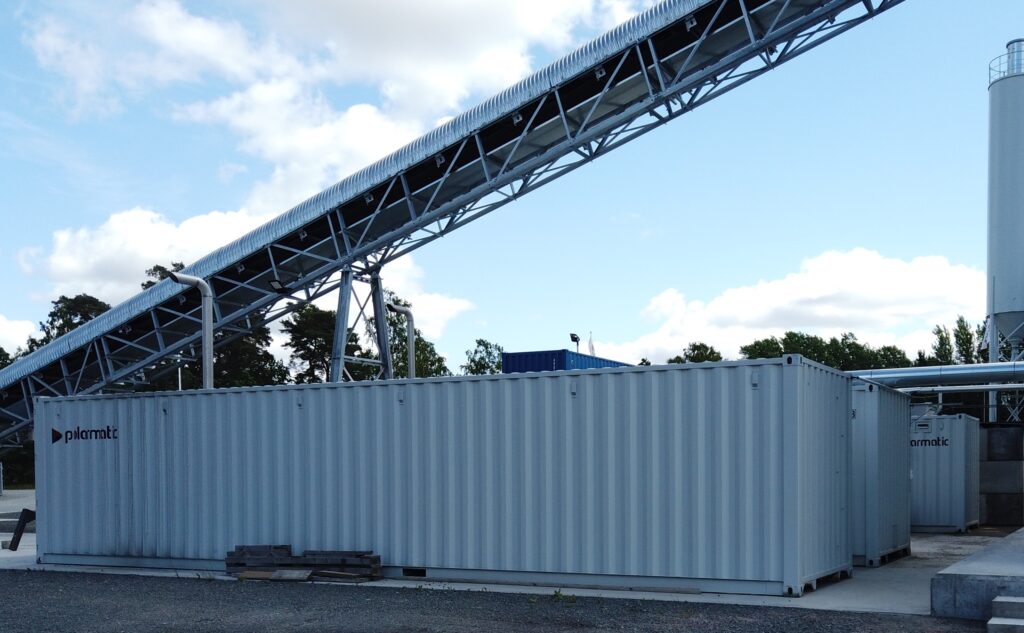

Swerock is one of the largest suppliers of materials and services for the construction industry in Sweden. Company’s annual turnover is approx. 6 billion SEK (587 MEUR) and it has about 1.300 employees. Swerock belongs to Peab corporation, and they have 42 batching plants in Sweden. In January 2020 Swerock opened a brand-new production facility in Skara, South-Western Sweden.

Polarmatic is glad to be a supplying partner for this new environmentally friendly, semi-mobile batching plant. Skara site heats all aggregates and water with Polarmatic’s Turbomatic, and both production and truck mixer fleet are controlled with ProConX control system.

Challenge

When planning of the new facility started, the project team had to consider the demanding sustainability requirements which Swedish authorities have set for the industry in Sweden. According to the latest environmental acts, every concrete batching plant needs to recycle and reuse the wastewater coming from washing of the mixers and trucks, all year round. In practise this means that, every concrete production site needs to be equipped with an inbuilt water recycling station.

Environmental aspects were also highly ranked in the project priority list, as the project team wanted to build an environmentally friendly concrete production plant. Part of this plan was also heating the aggregates with hot air with a system which is running on bio-fuels for the minimal emissions and good energy efficiency.

Solution

Swerock and Polarmatic had already been co-operating successfully for years, which made it easy for Swerock to contact Polarmatic when the planning process started.

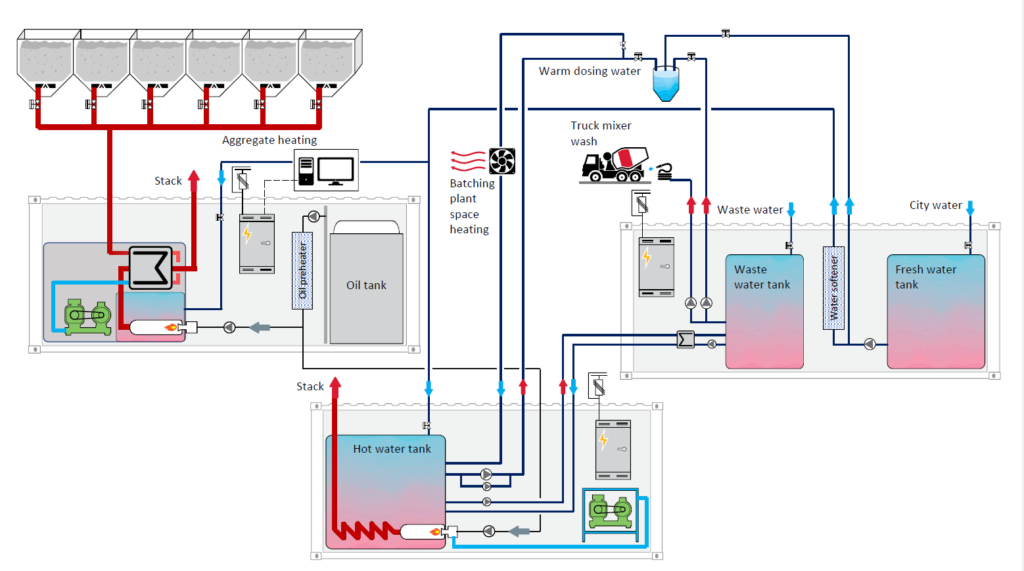

Polarmatic supplied the aggregate heating system, as well as the system for heating the recycled water. The wastewater recycling starts with the sedimentation of the wastewater, after which the water is led into Turbomatic heating system to be further reused in the mixing process.

The delivered Turbomatic is running on biofuel and system’s fuel efficiency is high, utilizing all the energy for heating the aggregates and batch plant, producing all the hot water that is needed for producing concrete and filling the truck mixers, as well as washing them.

Result

”When talking about the energy efficiency of the heating system we have; it is very good. We do not consume as much oil as they do in our other plants. And we must say also that one of the reasons why we chose Polarmatic was good price, a good economic solution. This Polarmatic solution has worked very well, even during the cold winter months.”

Fredrik Svensson, Regional Technical Director, Swerock AB

Technical Data

Solution

TURBOMATIC Warm Air Heating solution using biofuels and recycled water

Batching Plant

| Type | SBM Linemix 4000 |

| Number of Mixers | 1 pc, 4,0 m3 (141.3 ft3) |

| Number of Aggregate Bins | 6 pcs |

| Production Rate | 80 m3 (2825.2 ft3) / h at 15°C (59°F) concrete temperature |

| Ambient Conditions | Min. temperature: -5,9°C (21.4°F) Min. aggregate temperature -5,0°C (23°F) |

Heating Solution

| Total Capacity | 1,25 MW |

| Fuel | 100% RME |

| Structure | 3 x 40 ft sea container 1 x Water heating with warm air blowers PME-WAT 750 D 750 kW 1 x Aggregate heating system with temperature measuring system PAH-500 D 500 kW 1 x Water storage container Clean community water and recycled water |

Control System

| Polarmatic ProConX |