Photo by TIWAG via Kühtai project Mediathek.

Kühtai power station locates near the Austrian city of Innsbruck in the Austrian Alps, at an altitude of nearly 2000 m. In these challenging geographical conditions, the power station is currently working to expand its production capacity by 50% by the year 2026, with a strong focus on sustainability.

The expansion of the hydroelectric power station will be accomplished in three stages; Firstly, a 25 km long water diversion tunnel will be drilled and equipped. This will be followed by the formation of a new reservoir lake with a 113 m high dam. Finally, an underground pumped-storage power plant will be built to complete the expansion.

As a part of this extensive project, a concrete mixing plant and a mineral processing plant were constructed in the Kühtai valley. This approach was adopted to minimize the environmental impact of long-haul concrete transportation and to reduce overall emissions associated with the project.

The supply of these facilities was contracted with the Austrian company SBM Mineral Processing GmbH, which inaugurated the new container-mobile plants in 2021, showcasing their commitment to eco-friendly plant solutions.

Powerful Heating with Minimal Emissions

Considering the high altitude and the challenging Alpine climate, characterized by freezing winter temperatures, ice and frost, it is very essential to have a reliable and powerful heating system at the site that aligns with sustainability goals of the entire project. The heating system should enable concrete production with excellent concrete quality and properties throughout the year, even during the coldest winter days, without any unexpected disruptions in production.

Based on their vast experience in previous projects, SBM recognized the clear advantages of partnering with Polarmatic Oy, a company renowned for their sustainable heating solutions. Together, the companies equipped the production facilities in Kühtai with two robust TURBOMATIC heating units, ensuring superior concrete quality and minimal emissions for this special expansion project.

TURBOMATIC heating solutions are designed to be the most powerful heating systems available for the concrete industry, utilizing all the generated energy efficiently. TURBOMATIC systems operate without chimneys and there are no boilers, and the system minimizes emissions and promotes a cleaner concrete production environment. Polarmatic offers over 100 different system variants, supporting the use of various fuel options, including biofuels, which further reduce the already low emissions and the small carbon footprint, contributing to more environmentally friendly concrete production.

Superior Heating Power for Concrete Ingredients and Plant Facilities

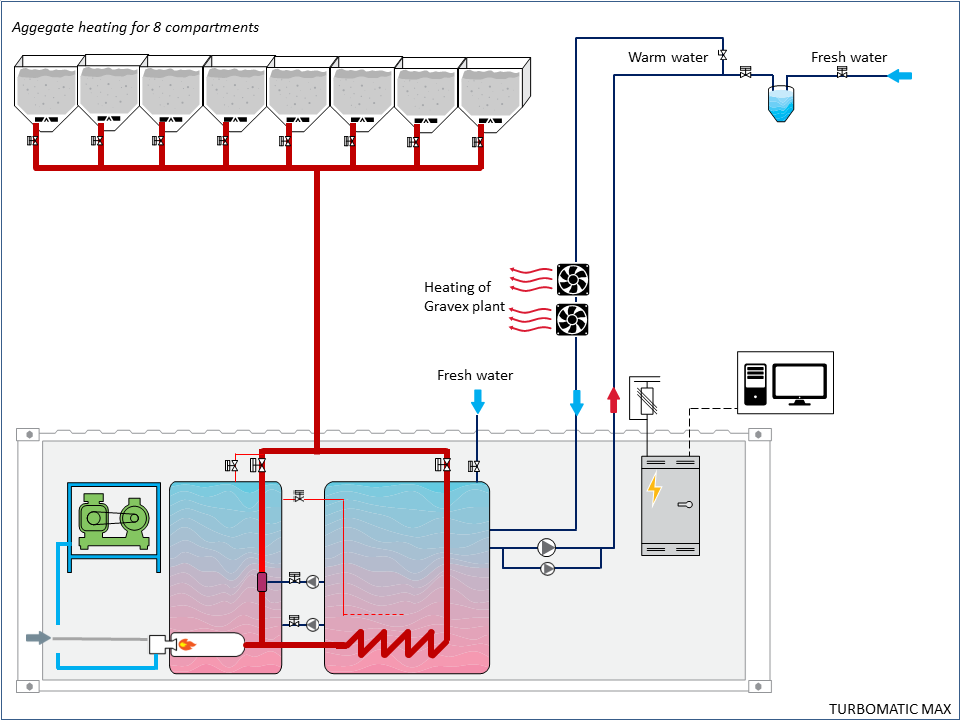

The first delivered heating unit in Kühtai is located at the mineral processing plant, where the on-site crushed, screened, and washed aggregates are heated using a TURBOMATIC PME-MAX 750 D. The containerized heating unit distributes heat to the aggregate bins and the processing plant facilities, ensuring comfortable indoor temperatures for the personnel to work.

Moreover, the heat generated by the TURBOMATIC effectively melts ice and snow from the aggregates stored in eight outdoor bins. Additionally, the system maintains the desired material temperature, ensuring they are always ready for immediate use whenever needed.

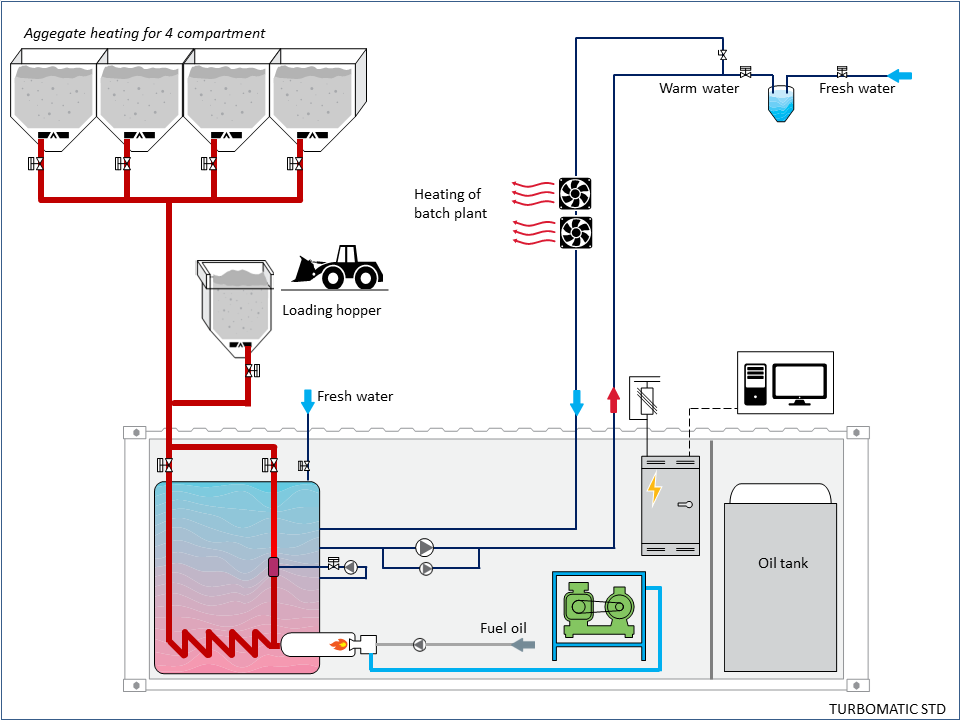

The second TURBOMATIC operates at the concrete mixing plant. PME STD 1000 DT heating unit quickly heats four silos to the optimal temperature, eliminating the productional delays related to the material temperatures. This heating unit, housed in a second-hand sea-container, not only warms the aggregates, but also water needed in the mixing process, and it also maintains a comfortable working environment within the batching plant facilities.

Partners for Sustainable Concrete Production

Through the strategic partnership between SBM and Polarmatic and the usage of sustainable heating solutions, the Kühtai power station expansion project demonstrates a holistic approach to renewable energy generation, minimizing environmental impacts, and promoting long-term sustainability.

Project Facts and Figures

- Kühtai reservoir: dam with bulk volume of 6.9 million m³, crown length of 510 m, dam height of 113 m, usable storage capacity 31 million cubic meters (mcm) of water

- Approx. 25 km of tunnels

- Power plant / powerhouse Kühtai 2: 80,000 m³ cavern excavation and 4 km tunnel

- Total concrete volume: >200.000 m³

- Installed power plant capacity 190 MW

TURBOMATIC PME-MAX 750 D

- Total Capacity: 750 kW

- Fuel: Fuel oil

- Features and Add-Ons: Plant heating, water treatment system, gas monitoring system

TURBOMATIC PME-STD 1000 DT

- Total Capacity: 1000 kW

- Fuel: Fuel oil

- Features and Add-Ons: Integrated 4.000 l oil tanks, heating of loading hopper, batch plant heating, water treatment system, gas monitoring system

I have been operating many batching plants during my career, and I really appreciate TURBOMATIC’s extraordinary heat output with high energy-efficiency. Both aggregates and mixing water are heated extremely quickly. The system is also very easy to control.

– Batching plant operator –