ProConX

The new generation ProConX™ concrete batching plant control system is the most modern and user friendly control solution available on the markets and it is developed specifically for, and in the co-operation with, the concrete industry.

ProConX is not like any other control system – instead it is developed to be intuitive, flexible, modern, responsive and easy to use. ProConX is of course equipped with all the features your plant needs for controlling the concrete production – and much more.

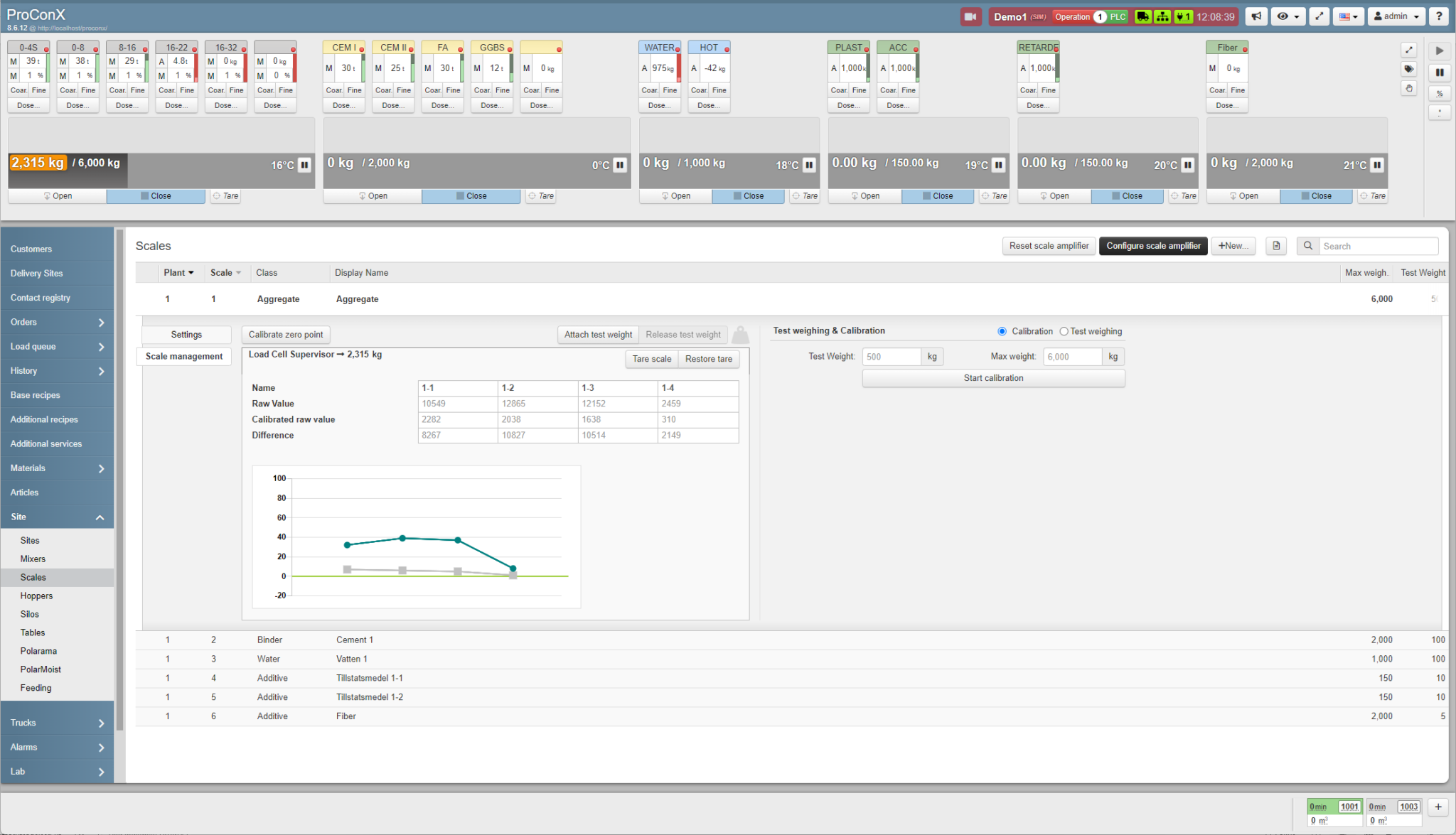

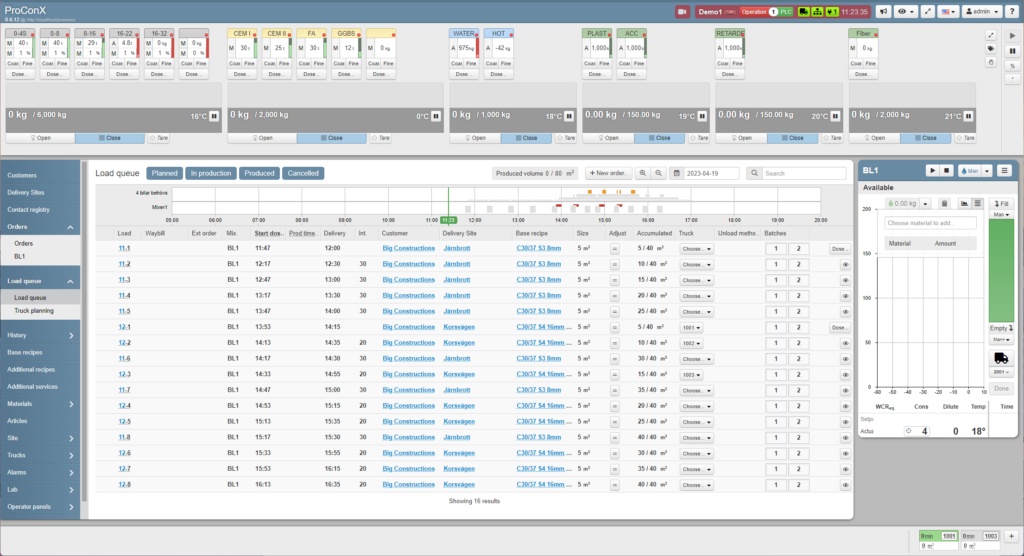

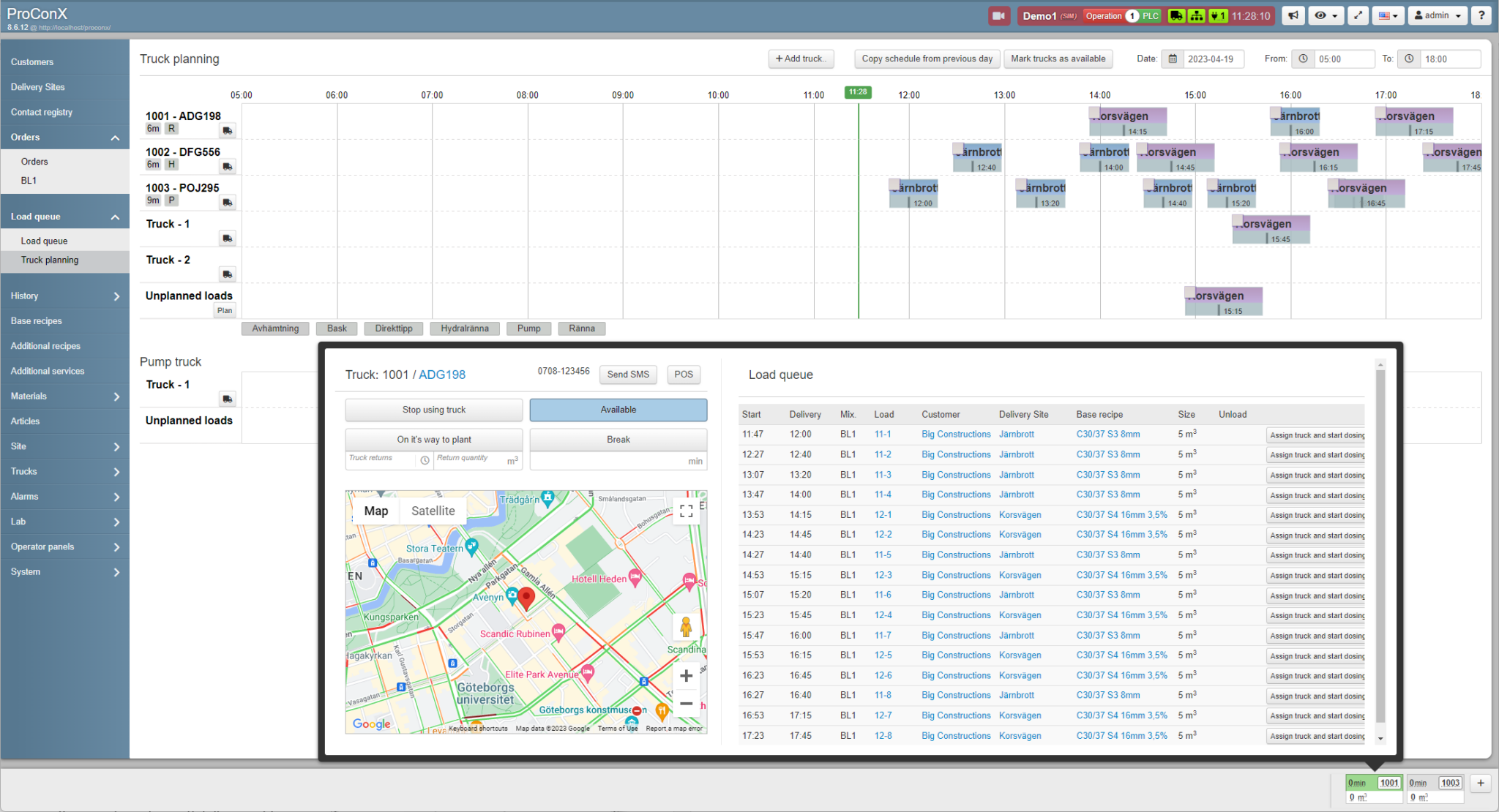

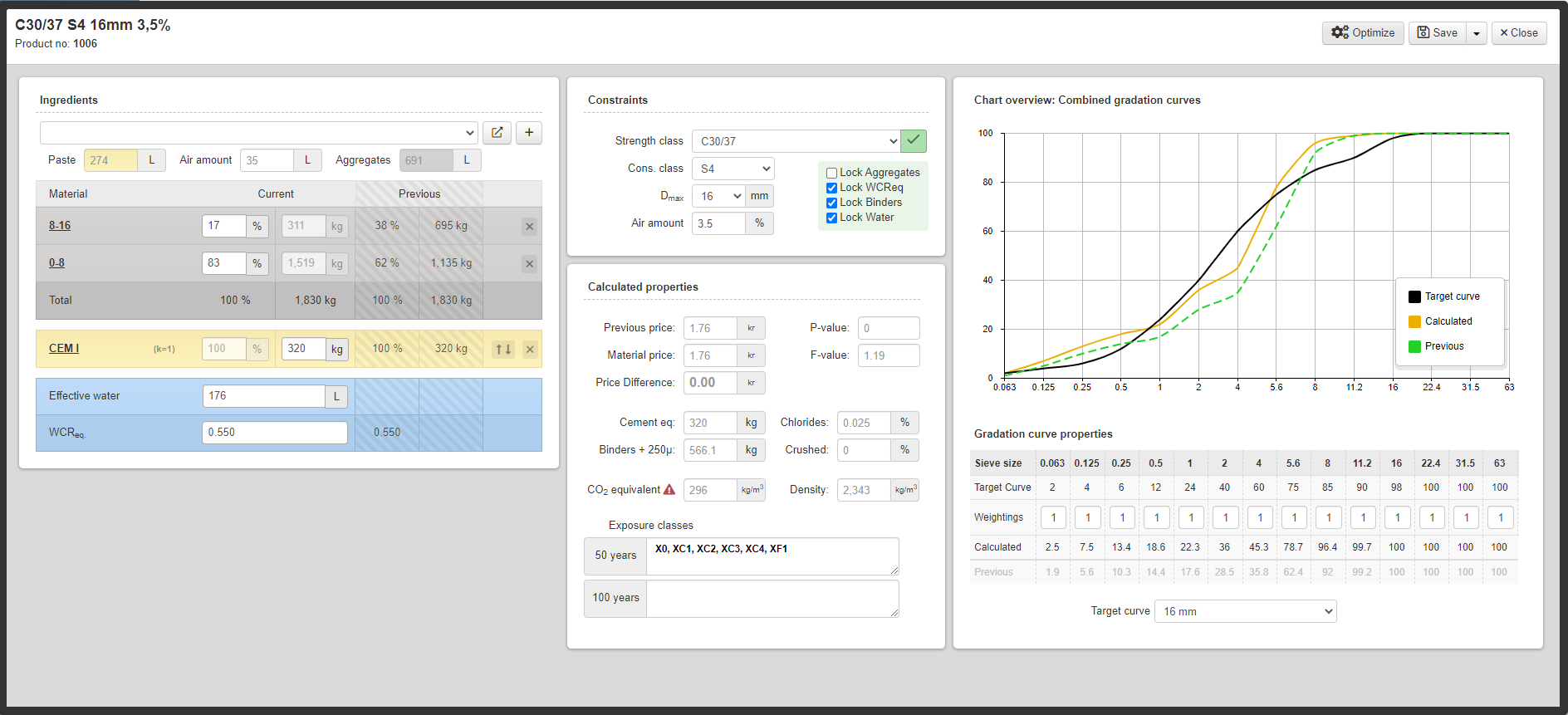

ProConX control system for concrete batching plants

- Is completely web-based and it can be accessed via any browser on a PC, tablet or smart phone.

- While producing concrete, data is shown on the background and only when the attention of the operator is needed, more details are brought up.

- Operator’s decision making is assisted by data and suggestions