Concrete Curing: Reliable Result in All Climates

In today’s demanding construction environment, where project deadlines are tight and quality standards are strict across diverse climates, achieving reliable concrete curing is essential.

Concrete professionals globally face the constant challenge of ensuring consistent strength development, durability, and performance of structures, regardless of unpredictable environmental conditions. The ability to overcome these operational pressures impacts directly project success, cost efficiency, and the long-term integrity of valuable assets.

Ineffective or inconsistent curing is a major obstacle, potentially leading to delays, costly rework, and compromised concrete quality. Uncontrolled variables like temperature fluctuations, humidity levels, and wind can severely hinder the concrete’s hydration process, preventing it from reaching its full potential. This highlights the critical need for a more controlled and optimized approach to curing.

Answering Challenge

Our approach to advanced curing technology provides the essential control required to mitigate these risks. By creating a precisely managed environment around the concrete, these systems ensure the curing process always occurs optimally.

This capability is vital for achieving predictable early strength development, ensuring uniform quality, and enhancing long-term durability, even when facing extreme cold, high heat, or rapid weather changes.

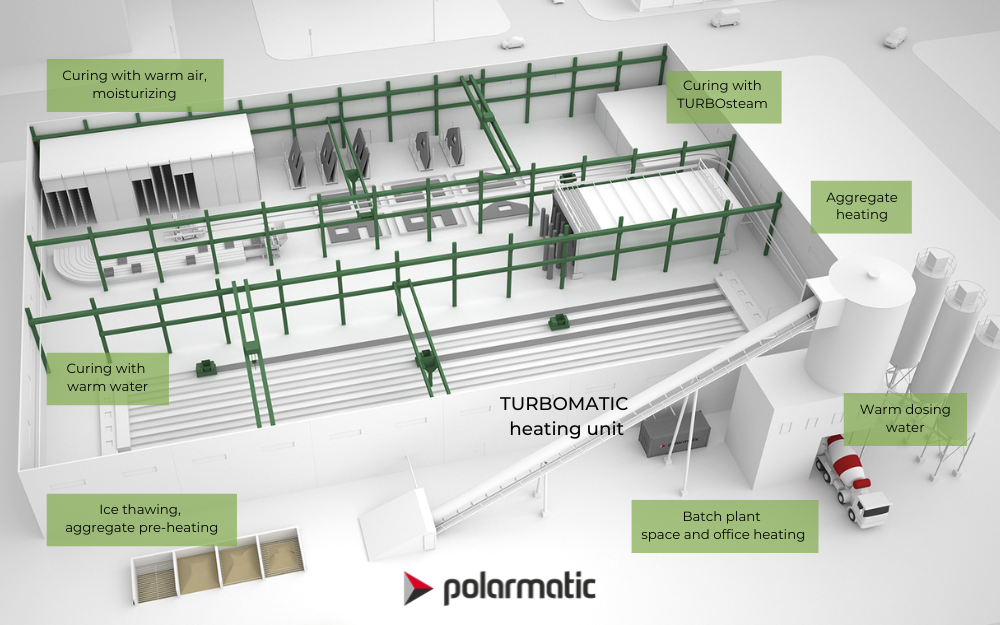

Drawing from our extensive expertise developed in challenging environments worldwide, Polarmatic’s technology specifically addresses these challenges. Our advanced and automated curing systems are engineered for reliability and efficiency, providing the means to maintain production schedules and quality standards under pressure.

With extensive data collection throughout the curing cycle, CUREMATIC ensures full traceability of the curing process by providing detailed reports. This helps the quality assurance experts to understand and trace any significant changes. It also helps with being transparent with customers and building trust throughout the supply chain.

We offer our CUREMATIC range, a comprehensive portfolio of advanced thermal curing solutions designed to tackle the concrete industry’s most critical challenges. Our systems, including energy-efficient Warm Water heating, versatile Hot Air curing and highly efficient CUREMATIC TURBOsteam technology, provide engineered answers for achieving reliable concrete performance.

Meeting Tight Deadlines and Managing Costs Effectively

The pressure to accelerate project timelines without escalating costs is a constant challenge. Unpredictable curing times can cause bottlenecks, delaying subsequent production phases. By integrating advanced thermal curing systems such as CUREMATIC early in the production process, we ensure accelerated and precisely controlled curing cycles.

This approach significantly reduces the time required for concrete to achieve its target strength, enabling faster stripping and quicker formwork turnaround. As a result, producers benefit from increased annual production rates, improved product quality, and more efficient operations throughout the year.

For professionals, this translates into increased production output and the ability to meet demanding schedules, directly contributing to cost savings by minimizing delays and improving resource utilization.

Ensuring Consistent Quality and Durability Across Varied Climates

Maintaining consistent concrete quality is non-negotiable, as rework is costly and damaging to reputation. External weather variability poses a significant threat to uniform curing and long-term durability.

CUREMATIC systems are engineered to provide a controlled curing environment, precisely regulating temperature and humidity. This critical control isolates the concrete from external factors – whether freezing cold, excessive heat, or strong winds – ensuring a homogenous internal structure develops. The result is reliable early strength, a superior surface finish, and significantly enhanced long-term durability, essential for the durability and performance of structures in any climate.

Promoting Sustainability Through Efficient Practices

As industry increasingly focuses on sustainable construction, the efficiency of curing methods becomes even more important. Inefficient curing can lead to wasted energy and materials.

Advanced systems, particularly technologies like CUREMATIC with TURBOsteam, are designed with energy efficiency in mind, leading to lower energy consumption per cubic meter of concrete cured and a reduced operational carbon footprint.

Furthermore, optimized, controlled curing helps minimize rejected concrete caused by poor curing, reducing material waste and the need for energy-intensive rework.

Implementing reliable, efficient curing directly supports the industry’s move towards more sustainable and responsible construction practices.

Would you like to discuss this further? Please contact us via: sales@polarmatic.com or one of our team members.