Starting 1. January 2026, all concrete production facilities in Norway must be fully compliant with the environmental requirements defined in Chapter 33 of the Pollution Control Regulations.

As many plants are still finalizing their preparations, we would like to let you know how Polarmatic can support you with practical, proven solutions. Together with our German partner AJF Group Engineering GmbH, we provide technologies specifically developed for concrete production environments and the regulatory expectations now coming into effect.

Key Requirements of Chapter 33 – What Your Plant Must Comply With

Chapter 33 of the Pollution Control Regulations obligates concrete producers to manage process water responsibly by reducing consumption, increasing recycling, and ensuring that all discharged and reused water meets the defined environmental limits. Concrete waste and sludge must be handled and stored safely, with clear rules for reuse and timely delivery. Plants must also control dust, runoff, and noise while maintaining the required documentation demonstrating compliance. In addition, all facilities must notify the regional authorities (Statsforvalteren) about their operations, and any significant changes in production.

Technology Supporting Compliance

CWAS Water and Sludge Treatment

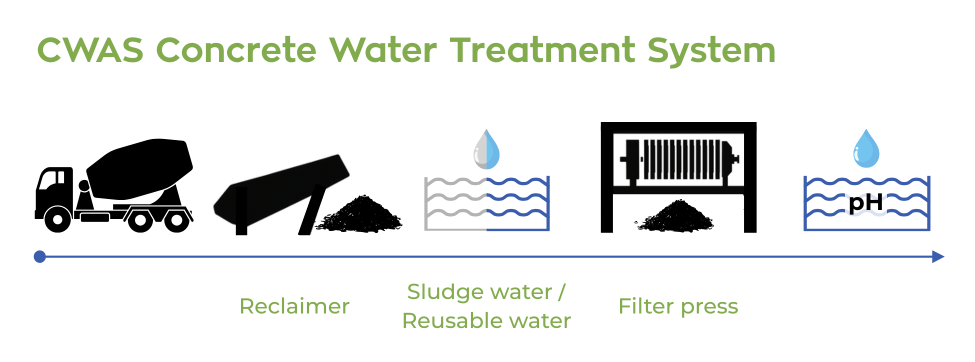

Through our collaboration with AJF Group Engineering GmbH, Polarmatic delivers the CWAS system – an automated and container‑based solution for water and sludge treatment, developed specifically for the concrete industry.

CWAS uses a filter press housed inside a winter‑proof container, enabling continuous year‑round operation. The system purifies residual water so it can be reused in concrete production while maintaining consistent and controlled water density – supporting both production quality and environmental compliance. Its fully automated process handles sediment extraction, filtration and optional pH regulation, allowing plants to meet the stricter water‑related requirements of Chapter 33 efficiently and reliably.

Additionally, CWAS minimizes waste by converting extracted sediments into reusable filter cakes, reducing disposal needs and contributing to a fully closed raw materials cycle.

Polarmatic delivers a complete range of equipment for wastewater treatment including the reclaimer, wastewater tank, and filter press – along with all components required for fully automated system operation.

Lear more about CWAS

POLARMOIST Moisture Sensors

By providing exact moisture measurements, contactless POLARMOIST sensor helps optimize the concrete mixing process. Accurate moisture data readings enable better control of the water‑cement ratio, leading to improved concrete strength, durability and overall quality. This ultimately results in reduced material waste and increased production efficiency.

Read more about POLARMOIST

TURBOMATIC Heating System

By delivering precise and energy‑efficient heat, TURBOMATIC solutions help reduce overall water usage, stabilize moisture conditions in aggregates and improve both batching accuracy and production reliability. Its performance contributes directly to the environmental goals of Chapter 33 by optimizing energy use, minimizing unnecessary water consumption and supporting controlled, predictable production conditions year‑round.

FIND OUT MORE ABOUT TURBOMATIC

We Are Here to Help You

If your plant is still looking for the necessary solutions to complete the requirements of Chapter 33, now is the ideal moment to finalize implementation plans. Together, CWAS, POLARMOIST, and TURBOMATIC form a strong technological foundation for meeting the new regulations while strengthening operational performance. Our team is ready to assist with evaluation, system selection, integration, and documentation.

Would You Like to Know More? Contact Us!