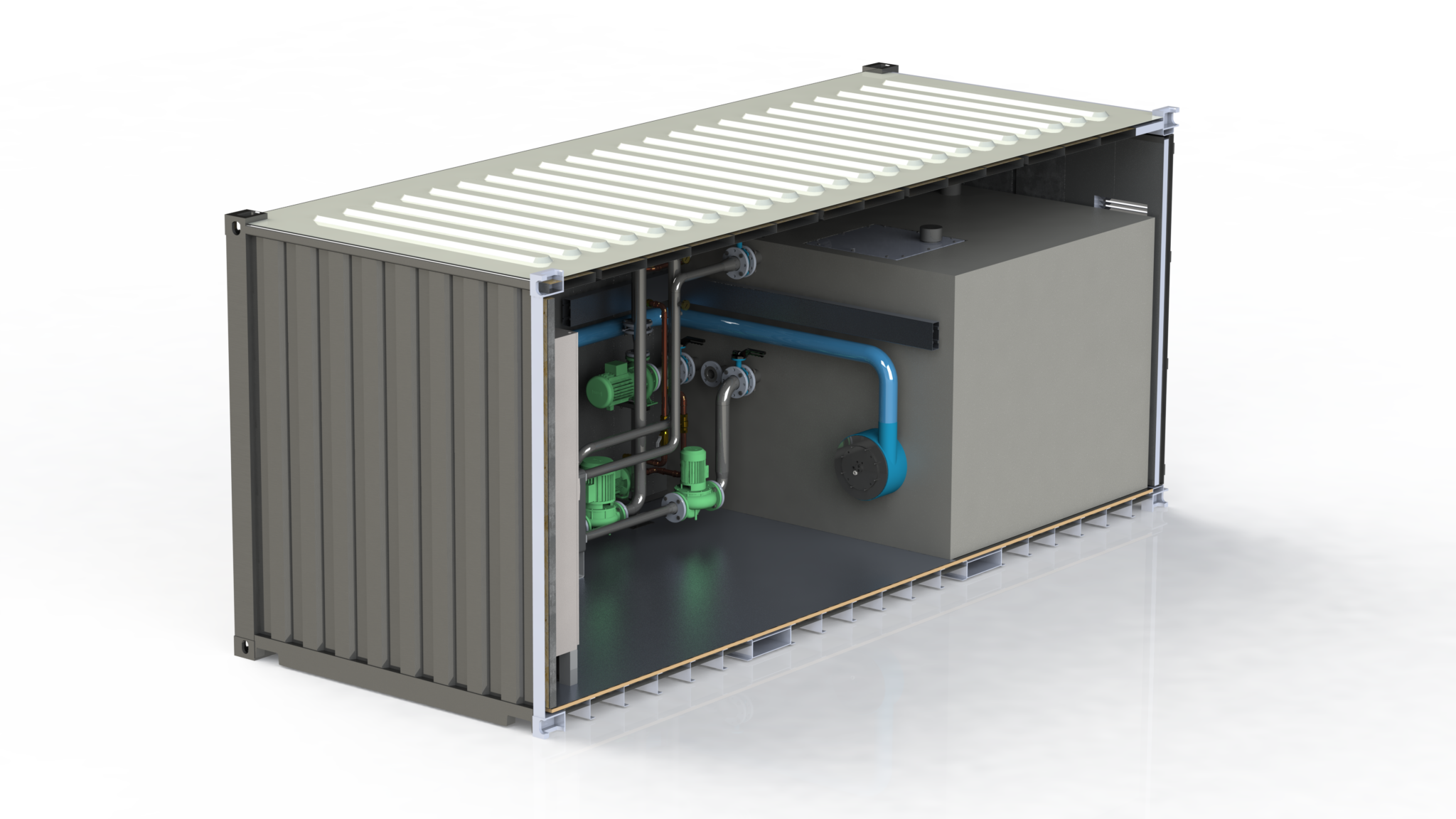

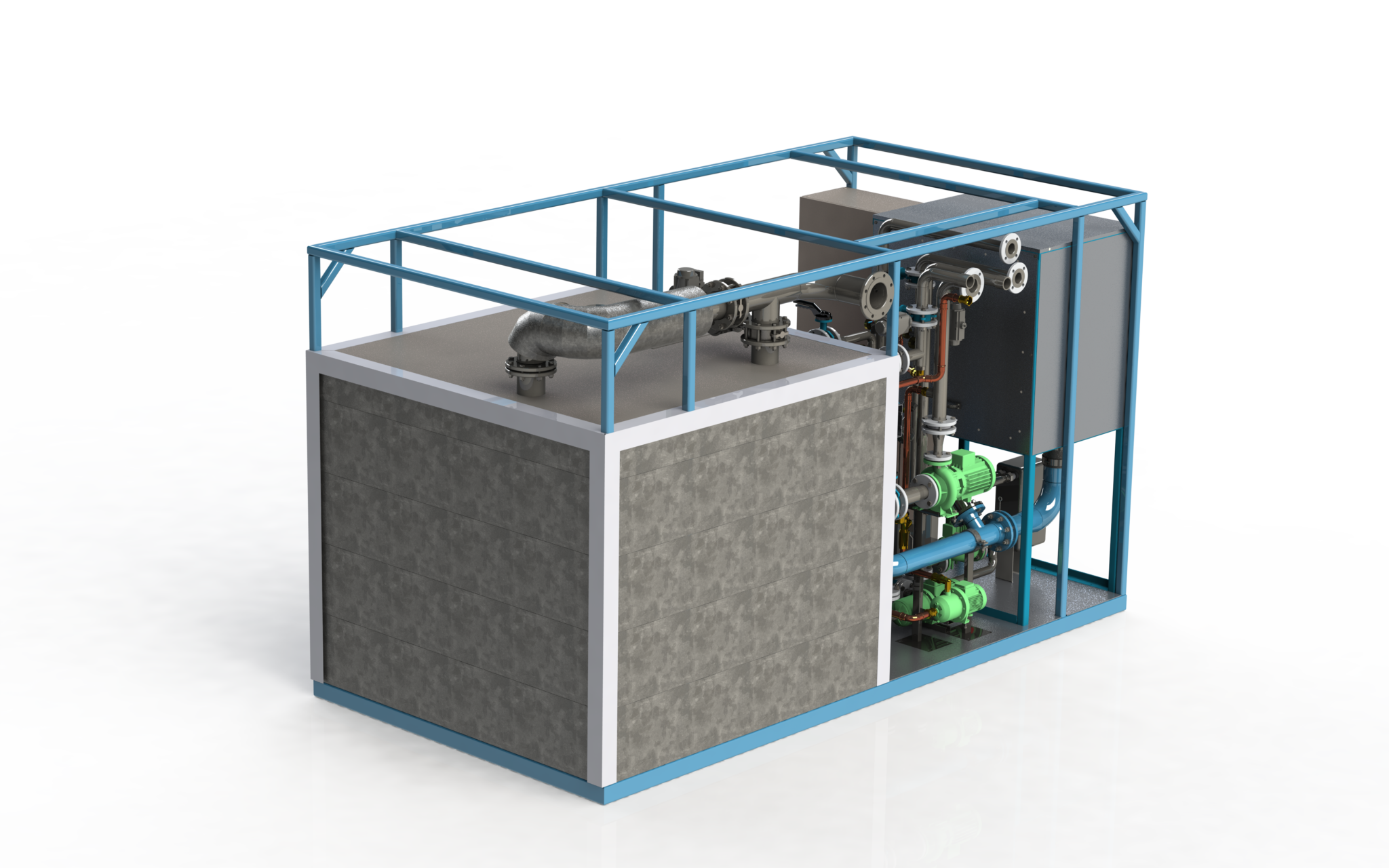

standardTURBOMATIC (STD)

TURBOMATIC STD is most commonly used for the heating requirements in moderate to severe climate conditions and/or for the applications with moderate to high heating power needs.

Typical applications

- Ready-mix concrete batching plants in moderate to severe climate conditions

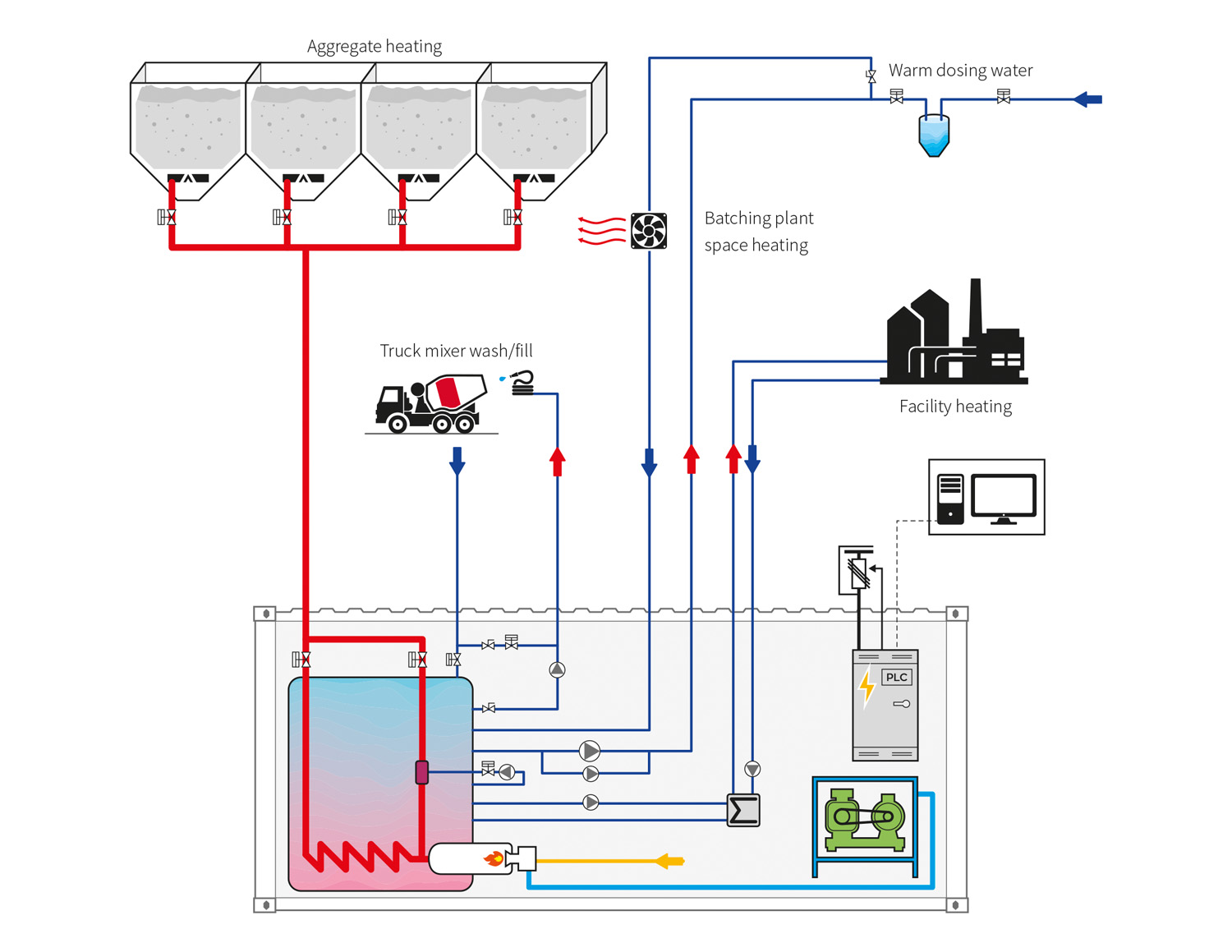

Main functions

- Aggregate heating with TURBOgas or -steam

- Generation of warm dosing water

Heating options

- Heating of the concrete batching plant production facilities

- Generation of warm wash and utility water

- Supply of warm water for filling the truck mixer saddle tank

- Heating of other batching plant facilities like offices and laboratories